There seems to be a lot of confusion and misconceptions about heat treated pallets, crates, and industrial lumber, as well as exporting packaging products. Do all pallets need to be heat treated? What is heat treating? When is it used? We’re going to try to clear things up for you here.

Let’s Talk Kiln Drying

Before we get into heat treating, it’s worth noting that all wood is treated in order to cure it and dry it out before use. It’s called kiln drying, and it’s intended to reduce the moisture content of the wood. To do that, treaters place stacks of lumber inside large kilns the size of a room. The wood is then heated to evaporate and remove moisture.

Essentially, they are curing the wood to help prevent excessive warping and reduce the weight of the lumber. Kiln drying has nothing to do with sterilization. In general, the wood isn’t treated long enough, or at high enough temperatures, to effectively sterilize it. Kiln drying is only done to cure lumber and make it ready for use.

Heat Treating Lumber

In contrast to kiln drying, heat treating lumber, pallets, and crates sterilizes them. Heat treating is a phytosanitary process that heats products to a core temperature of 140 degrees for a minimum of 30 minutes. This ensures that all insects and insect larva are completely eradicated from the wood.

Phytosanitary standards are controlled with a set of guidelines for regulating wood packaging materials in the international community, called the International Standards for Phytosanitary Measures No. 15 (ISPM15). ISPM15 is part of a treaty recognized by the World Trade Organization as a measure to prevent the introduction and spread of pest and other organisms. Heat treating, or fumigation, is required for all export wood packaging materials that are used in international shipments.

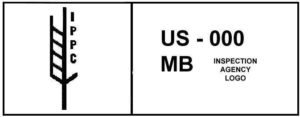

Once wood packaging has been treated, with either heat treating or fumigation, it is stamped. The ISPM15 stamp is commonly applied as an ink stamp, stencil or brand, and is made clearly visible on the exterior surface of the wood packaging. The ISPM15 stamp must be applied to a minimum of two opposite sides of a completed wood packaging solution to certify that all solid wood has met the treatment requirement.

Once wood packaging has been treated, with either heat treating or fumigation, it is stamped. The ISPM15 stamp is commonly applied as an ink stamp, stencil or brand, and is made clearly visible on the exterior surface of the wood packaging. The ISPM15 stamp must be applied to a minimum of two opposite sides of a completed wood packaging solution to certify that all solid wood has met the treatment requirement.

If you have additional questions about how ISPM15 works and if it applies to your wood packaging, please check out our Frequently Asked Questions here.

Do all pallets need to be heat treated?

So, let’s get back to the original question: Do all pallets need to be heat treated? The short answer to this question is no.

All the wood used to make pallets is kiln dried to cure it, but that does not meet phytosanitary standards, and is not considered heat treating. For pallets that will remain inside the United States and products that will never be exported, no heat treating or fumigation is required. Only pallets (or lumber, crates, and other forms of wood packaging) that will be exported to other countries need be heat treated.