If you use industrial lumber or wooden pallets in your manufacturing process, then I am sure you are no stranger to mold. Mold is a fact of life where wood is involved. Mold can damage products, contaminate production lines, and even cause health effects to the people that handle it.

Orange mold is no different from other molds, except it particularly likes to grow on lumber, so it is imperative to keep a close eye out for it. This article will cover what it is, the types of orange molds, how to prevent it from growing, and what to do if you spot it!

What is Orange Mold?

Mold is a part of the fungi kingdom and a natural part of our ecosystem. It plays an integral role in breaking down dead organic matter. Mold can appear indoors or outdoors, basically anywhere moisture and oxygen are present. Wood is susceptible to mold growth when left in an environment where excessive moisture can accumulate.

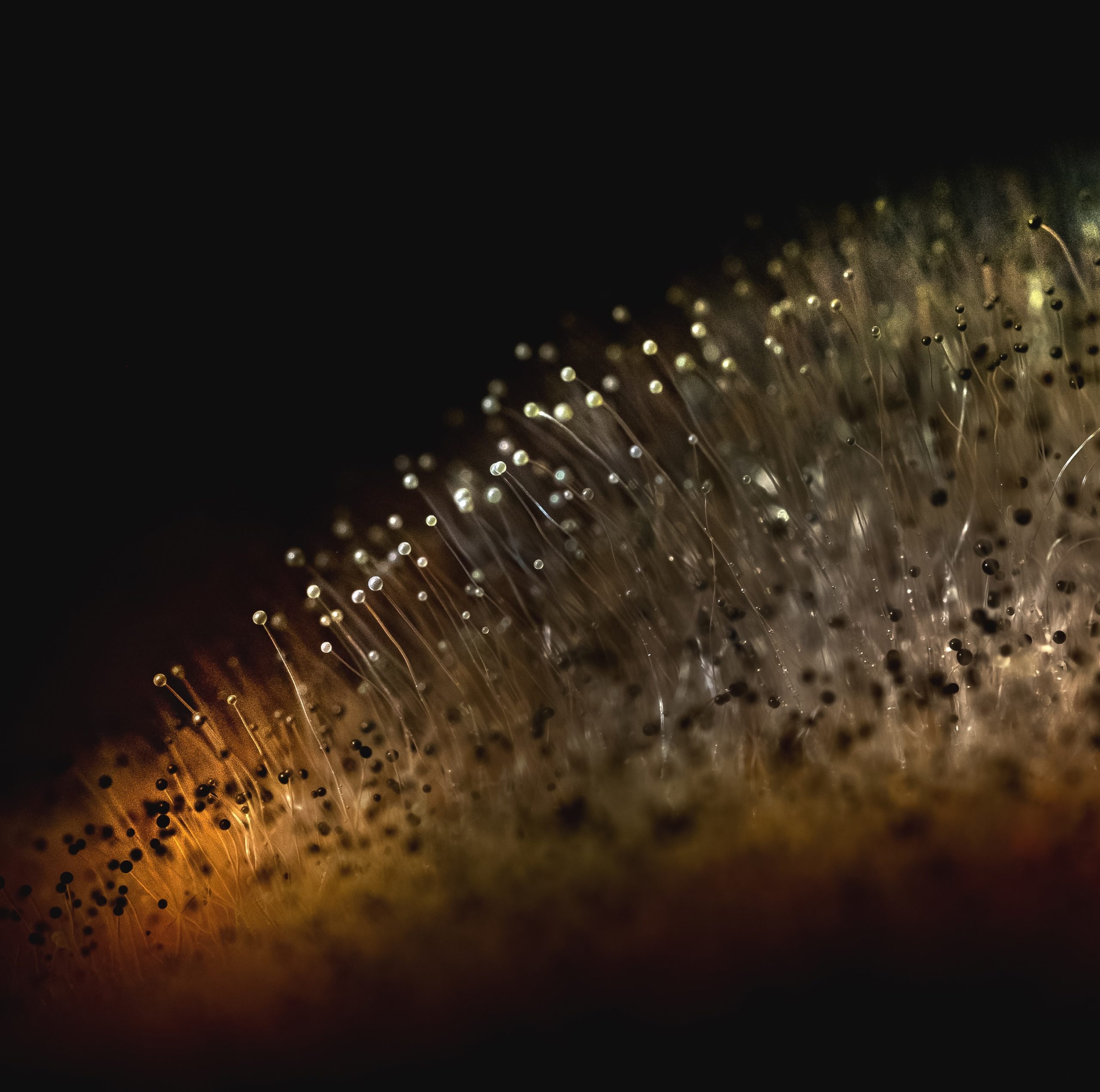

Wood is susceptible to mold growth when left in an environment where excessive moisture can accumulate. Click To TweetOrange mold is a general name that is given to filamentous fungi and fungi-like organisms that develop orange spores. Mold can be different variations while producing the same colors, here are the differences:

Types of Orange Mold

This is a group of saprophytic and opportunistic molds that do not produce a dark pigment. It is a common fungus found in soil, lumber, and rotting plant materials. The colonies formed in this particular group of fungi can be orange, yellow, and pink. This group is mostly found outdoors but can be found indoors when humid conditions persist.

Human infections with acremonium are rare and usually present in people that are immunocompromised. Higher temperatures, higher humidity, and frequent exposure to A. strictum all increase the risk of infection.

This is another group of saprophytic fungi that can be used as an antifungal against other pathogenic fungi, supporting root growth and controlling sugarcane pathogens. It produces felty colonies in bright shades of yellow, orange, red, brown, and black. It can also proliferate, reaching 6 cm in two days at room temperature. It can be found in the soil of the Americas, Asia, and Europe.

Epicoccum nigrum can cause adverse health effects, especially related to inhalation of the fungus. It is known as a significant indoor and outdoor allergen, having been found in many samples of human skin and spit. It does not usually cause a systemic infection, but it is better to take care of it if you suspect that it is around.

Aspergillus molds are the most notorious of the orange mold types. They are known to reproduce at elevated temperatures, low water availability, and with high concentrations of sugar and salt. This adaptability is what makes them more prevalent than other types of orange mold. Statistics show that this type of orange mold is most likely to be inside houses and buildings.

Aspergillus molds can cause serious health issues in humans and animals because of the aflatoxin that is produced, which is both a toxin and a carcinogen. Aspergillosis is a disease caused by Aspergillus and includes symptoms such as fever, cough, chest pain, and breathlessness. This fungal infection is considered one of the best theories of why early Egyptologists and tomb explorers died after being in the tombs for extended periods of time. Many people believe it is because of the “curse of the pharaohs,” but toxic mold is a more scientific hypothesis.

The creepiest type of orange mold is found within a slime group of organisms. They are fungi-like organisms but belong to the kingdom of Protista. This is an ancient group of organisms that are not a part of the animal, plant, or fungi kingdoms. Due to this, slime molds are unique and can be very different in appearance. This type of mold feeds on bacteria and other microorganisms in nature and grows on food sources that have been exposed to moisture.

This type of orange mold is most likely to grow on trees in nature and you are not at a big risk of lumber that has already been processed. You may see this type of orange mold on lumber before it goes to a sawmill to be treated. It is considered an allergen to humans and should be dealt with if found.

What Causes Orange Mold?

Four components lead to mold growth- moisture, oxygen, heat, and a food source. Orange mold is more likely to grow on wood than other types of organic material, so you must be vigilant with any industrial lumber that you use. Wood packaging stored in an environment with 60% humidity, or more, is at greater risk of being contaminated with orange mold. Testing has shown that wood with a moisture content above 19% for more than a week is at significant risk for mold growth.

Temperature is another important factor in orange mold growth. The ideal temperature for mold to begin to form is between 70 and 85 degrees Fahrenheit. Manufacturers often have difficulty keeping wood packaging outside of this temperature zone, so it is crucial to keep moisture in check anywhere near wood packaging and products.

Preventing Orange Mold

As people say, the best offense is a good defense. The best way to deal with orange mold is to prevent coming across it, to begin with. There are steps you can take to prevent mold on any industrial lumber that is a part of your manufacturing process. Here are four tips to save time and money by avoiding orange mold growth!

1. Kiln Dried vs. Heat Treated Lumber

Kiln drying is the first prevention method that should be used. This is when lumber is stacked inside a large, heated room until the wood has less than 19% moisture. This method is to prevent warping and lower weight. It is not a sterilization practice but helps prevent mold by reducing dangerous moisture levels. Kiln drying will work well to get most moisture out of the lumber, but it does not protect against future contamination with moisture exposure.

Heat treated lumber is different than kiln drying because it is used as a sterilization process. Wood is entered into a chamber and kept in high heat for 30 minutes. This eliminates all insects, pests, and mold that may be currently on the lumber. Heat treatment is what is required by the ISPM 15 stamp, but the stamp does not restrict mold. This is because even though it kills mold during the process, there is no protection from future mold contamination.

Kiln drying is a better preventative of orange mold growth because it takes moisture out of the wood. Heat treatment does not affect the moisture of the wood and it should be kiln dried before being heat treated. Since all surface organisms are killed in the process, any mold spores that land on the wood after treatment can grow competition free. Therefore, after heat treatment wood products must be kept out of the mold danger zone because they can be at a higher risk for orange mold growth. Heat treatment is good if there is mold currently on the lumber that needs to be killed, but kiln drying is the superior mold preventative.

2. Chemical Treatments

There are many chemical treatments on the market that can help to protect against mold growth for three to six months, depending on storage factors and environmental conditions. The chemicals are applied by spraying or dipping the lumber shortly after cutting. Some industries prohibit these chemicals, so make sure you check the regulations that you must follow with wood packaging and products.

3. Mind the Weather

This is the most important tip for preventing orange mold growth on industrial lumber. Wood that is exposed to the elements consistently will be at a high risk of mold contamination. Storing your products in a dry, covered place with good ventilation is key to the longevity of wood products. Also, lifting wood products off the ground can help to prevent the bottom from encountering standing water.

If you do not have a place to store wood packaging or other products, check with your supplier about JIT, or Just-In-Time, deliveries that will bring you the exact number of products that you need at a time to prevent a lack of storage and mother nature from ruining products.

4. Buy New Instead of Recycled

If you work in an industry that has restrictions on mold found on wood packaging, it may be best to get rid of the moldy product and replace it with a new one. This is especially true for pallet manufacturers that have strict rules against mold. Recycled pallets may be cheaper, to begin with, but they are more likely to deal with mold and other issues. Mold can even be inside the recycled pallet where you cannot see it. New pallets and wood products are the better choices in the long run.

Life Happens… What’s Next?

So, you encountered some orange mold on your industrial lumber? Life happens and it is okay!

Even when you’ve taken steps to prevent orange mold, it can still show up. You will inevitably come across mold from time to time when working in the lumber industry. Some good news is that it is not likely to diminish the strength of the wood and can be remediated.

To eliminate the orange mold, you can first pressure wash the lumber with a diluted bleach solution. This will remove the surface mold growth but will not prevent it from coming back because it cannot get to the deeper layer. After the pressure washing, you can use a chemical solution that is strong enough to reach all the mold and eliminate it. This is not a sustainable solution because the root of why the mold showed up must be solved, or it will continue to come back.

Before You Go

The best way to avoid orange mold is to prevent it from growing in the first place. Moisture is your number one enemy and must always be avoided. Work with a trusted lumber supplier, so that you can work out the best strategy for your manufacturing process to run orange mold-free.

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)