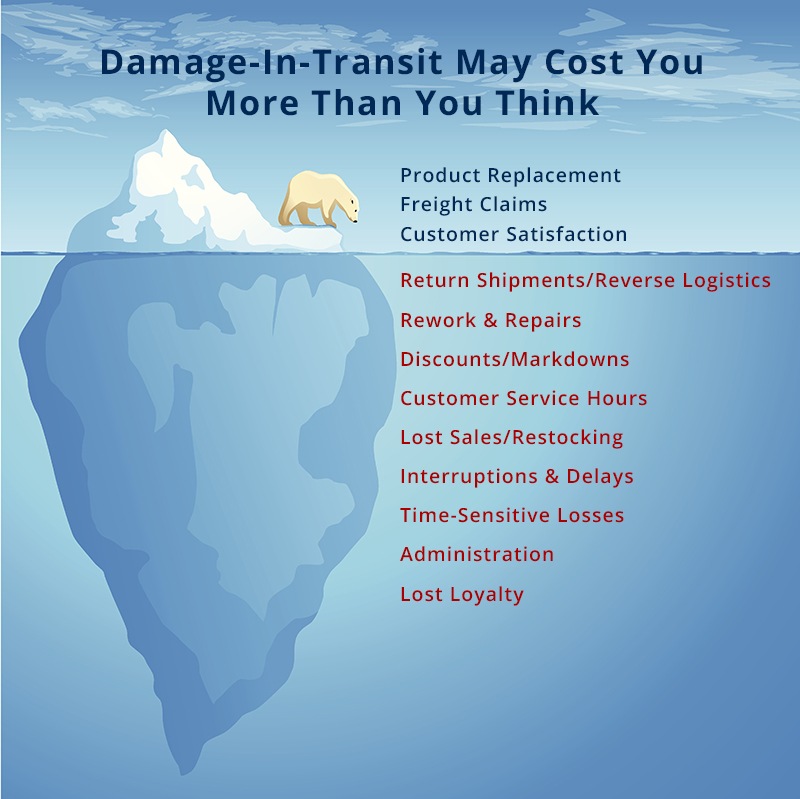

What does in-transit damage really cost your company and supply chain each year? While some damage may be covered by insurance, the actual cost is probably far greater than most businesses realize because it causes a ripple effect throughout the business.

According to Packaging Digest, “As much as 11% of unit loads arriving at a distribution center have some level of case damage.” While damage in-transit is often thought of as a logistics problem, the root of the problem may actually be in your packaging design, material handling policies, or storage procedures, long before transportation gets ahold of the product.

Supply chain managers want to safeguard products against any potential damage because they know that damage in-transit hurts their own cost center. Unfortunately, many managers don’t fully realize the wider repercussions of damaged items. Damage in-transit costs American businesses millions of dollars every year, but the ripple effect can be far more costly in direct and indirect expenses.

Direct and Measurable Costs of In-Transit Damage

Calculating your fixed damage costs can be a tedious exercise, but it’s well worth the effort. In order to get an accurate accounting of the true cost of in-transit damage, you have to make sure that you’re looking at all the costs associated with it. When you know all the costs, it becomes much more straightforward to calculate the cost to the business of each damaged unit.

Calculating your fixed damage costs can be a tedious exercise, but it’s well worth the effort. In order to get an accurate accounting of the true cost of in-transit damage, you have to make sure that you’re looking at all the costs associated with it. When you know all the costs, it becomes much more straightforward to calculate the cost to the business of each damaged unit.

Below are some of the factors that you’ll need to calculate. Your company may have additional elements to factor into the cost.

Use all of these factors to determine the total product cost of damage per unit. Once you have that number, you can multiply it by the average number of units that are damaged for a given time period. That will be the total damaged product costs to your company for that time period, whether it’s a month, quarter, or year. This calculation can also be used to figure out how much the damaged product costs eat into your company’s profits.

For most companies, this is a pretty eye-opening exercise.

Indirect Costs of In-Transit Damage

There are a lot of indirect costs of in-transit damage that are more difficult to define. You may not be able to put a specific number value on the indirect costs, but your company will certainly feel them.

Lost Productivity

Dealing with damaged products and their subsequent return can be a real hit to your company’s productivity. Employees spend hours filling out claims, tracking down return orders, repackaging and shipping replacements, etc. In most cases, dealing with product damage and returns is not the primary job of the employees assigned to these tasks.

Those employees are losing productivity in their primary duties. It can be hard to calculate this loss, but if the percentage of damaged products is significant, the intangible cost to productivity could be pretty significant too.

Damaged Products = Damaged Relationships

Receiving damaged products, and the delay and hassles that situation causes, may ultimately affect your customers’ future buying decisions. This is especially true in business-to-business relationships where your products are a component that another business needs for its own production. Receiving a damaged shipment may shut their production lines down, and that can be devastating to your relationship with the customer.

In that kind of scenario, the manufacturer may not be able to wait for replacements. Depending on your relationship with the customer, you may be held responsible for production downtime and be penalized financially. Worse still, your customer may lose faith in your commitment to quality and take their business to a competitor.

Damaging Sales and the Brand

We’ve already discussed how receiving products damaged in-transit can hurt your customer relationships. It’s not a long stretch that losing customers due to product damage hurts future sales to that customer. Unfortunately, there are other ways that in-transit damage hurts your sales department.

Products damaged in transit also result in a reduction of inventory available, and that can cause lost sales, lost market share, and a negative impact on the brand image.

Speaking of your brand, how often can you deliver damaged products to your customers before it starts to hurt your brand? No one wants to buy from a company that doesn’t adequately protect its products, and it doesn’t take very long for the word to get out and damage your reputation.

To make matters worse, in many companies, the salespeople don’t just close deals, they also manage the account. Whenever a customer receives damaged products, the salesperson (or account manager) must spend valuable sales time pacifying the customer. That cuts into the time that salespeople can use to prospect and close new customers.

How to Reduce In-Transit Damage

While there are lots of factors that you can look at to reduce in-transit damage, such as your material handling procedures, how products are stored, or the mode of transportation, it all starts with your protective packaging. If your product is adequately protected, then you’ll have a significant reduction in damage due to any of the other elements you’re considering as likely culprits.

If your products are frequently being damaged before they get to your customers, then an integrated packaging solution may be your best option to mitigate that damage before it can occur.

It’s not unusual for a company to start with the least expensive packaging option, only to realize that their in-transit damage is too high and their packaging isn’t sufficient. That’s why it’s important to take a total cost approach to packaging. Taking a total cost approach means that you’re not only accounting for the initial cost of the packaging itself but also factoring in the cost of in-transit damage.

The idea is to find that packaging sweet spot where your packaging is the most efficient and effective, at the minimum packaging cost possible. The right packaging solution for your products will also consider those other factors that affect in-transit damage, such as product storage, material handling procedures, and mode of transportation.

Once you find that sweet spot, you’ll drastically reduce the number of products damaged in-transit as well as the severity of the damage.

In Conclusion

For many companies, the cost of in-transit damage is much higher than they realize. While it’s true that some of the damages may be covered by insurance, the real cost of damaged and returned products causes a ripple effect throughout the business, resulting in millions of dollars lost in both direct and indirect costs.

The only way to truly mitigate damage in-transit is to ensure that your products are properly protected with the right industrial packaging solution.