If you don’t live and breathe pallets the way we do at Conner, you may not know the difference between 2-way vs 4-way pallets. It’s one of the most frequently asked questions we get from people who are interested in purchasing pallets from us.

Fortunately, the answer is pretty simple.

2-Way vs 4-Way Pallets: What Does That Mean?

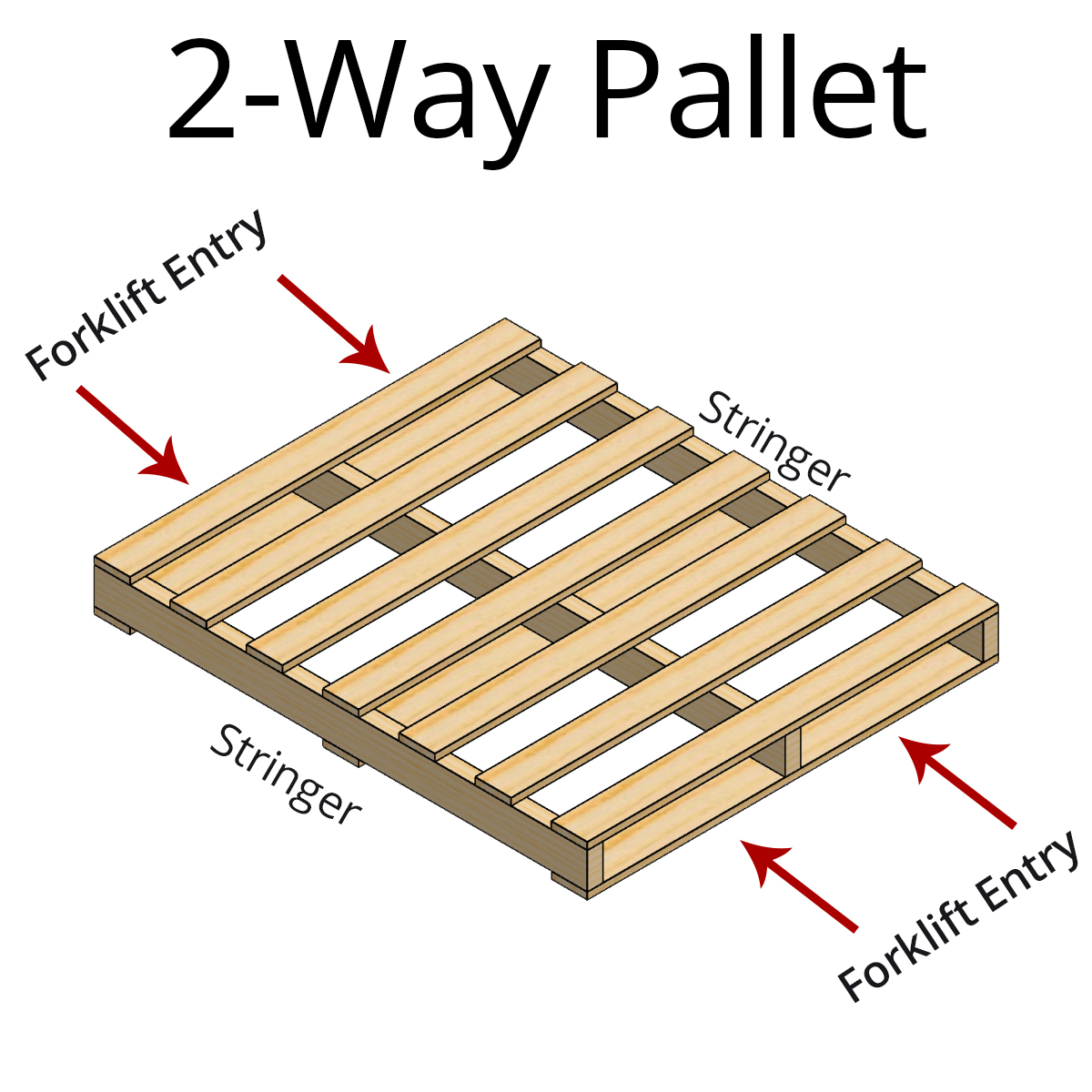

All wooden pallets are built to be either 2-way or 4-way pallets. The construction for each type of pallet is different, and the difference all comes down to how the pallet can be picked up. Forklift tines and hand truck tines must get under a pallet in order to lift it up and move it. How those tines can enter a pallet and get under it determine whether it is a 2-way vs 4-way.

Stringer pallets, with solid stringer boards, only have an opening on two sides where tines can enter. Stringers are the horizontal boards that support the pallet’s deck. Stringer pallets typically have one middle stringer and stringers on each side. When these stringers are solid, without notches cut into them, forklift tines can’t enter the pallet through the stringer sides.

If a forklift or hand truck can only get under a pallet on two sides, then it is a 2-way pallet.

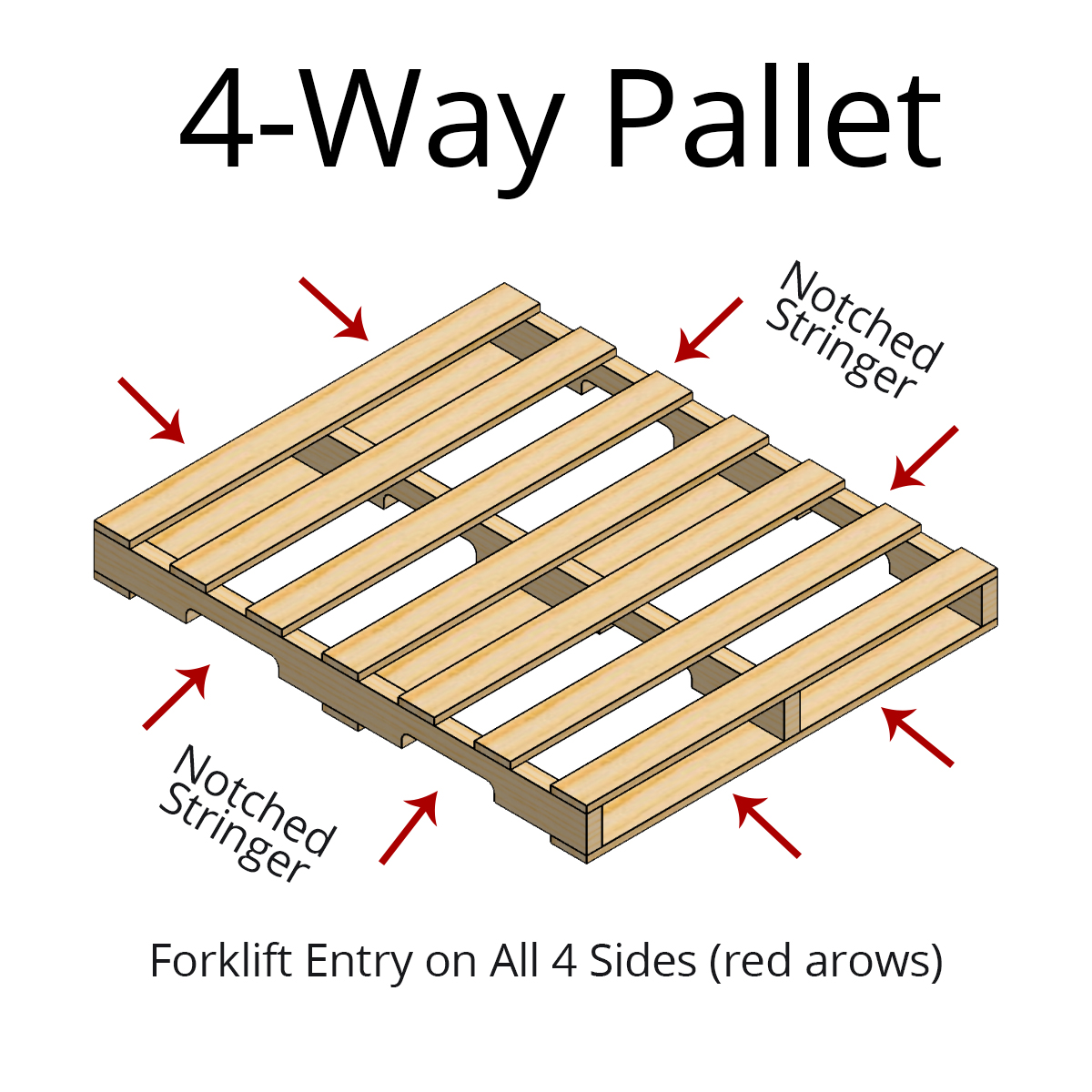

On the other hand, stringer pallets with notched stringers allow the tines to enter on all four sides of the pallet. If a forklift or hand truck can get under a pallet on all four sides, then it is a 4-way pallet.

Block pallets use blocks to support the deck, rather than stringers. Block pallets are also 4-way pallets because the tines of a forklift or hand truck can enter the pallet on all four sides. The image at the top of this page is of a 4-way block pallet with a hand truck.

2-Way vs 4-Way Pallets – Which is Better?

Both types of pallets are used in a wide variety of manufacturing and commercial applications. The major reason why one type of pallet would be chosen over the other is how that pallet will be handled and what works best for a particular facility and application needed.

In many cases, the equipment or layout of the facility makes one type of pallet better than the other for that manufacturer. If space is at a premium, a 4-way pallet may make more sense because palletized products can be moved within the facility more easily with less space.

- 2-way pallets are generally more economical to manufacture.

- Forklifts need more space to maneuver to line up and get under a 2-way pallet.

- Palletized products must be lined up in a particular way at the facility, or on a truck, to allow the movement of 2-way pallets. That makes full space utilization more difficult.

- Some types of manufacturing automation only accept 4-way pallets.

Wrapping It Up

That’s all there is to it. The difference between 2-way vs 4-way pallets boils down to how many sides on which a forklift or hand truck can enter the pallet — simple as that. Choosing the right type of pallet will largely depend on the specific needs of your facility, how much space you have, and how the pallet will be used. Our design team can help you figure that part out whenever you’re ready.

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)