People often use the words “pallet” and “skid” interchangeably, but there is actually a pretty big difference between the two. While you may not really care about how to identify the difference between a pallet or skid, each type of wood packaging is better suited to different situations. Knowing the difference helps to ensure that you’re using the best one for the job.

We created the short video above to quickly explain the differences, but let’s go into a little more detail here.

It’s All in the Deck Boards

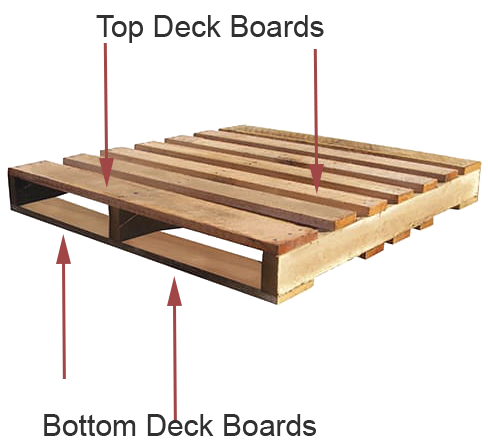

Although there are several minor differences between a pallet or skid, mostly related to their usage, the biggest thing that differentiates them is the deck boards. Deck boards are the platform where you put the goods that you’re palletizing.

When it comes to pallets, there are deck boards on both the top and the bottom of the pallet. That means that when a pallet is sitting on the ground or floor, it’s sitting on the bottom deck boards, the product is sitting on the top deck boards, and there are stringers sandwiched in between.

Is it a pallet or skid? Is there really a difference and does it matter? Share on XPallets have top and bottom deck boards.

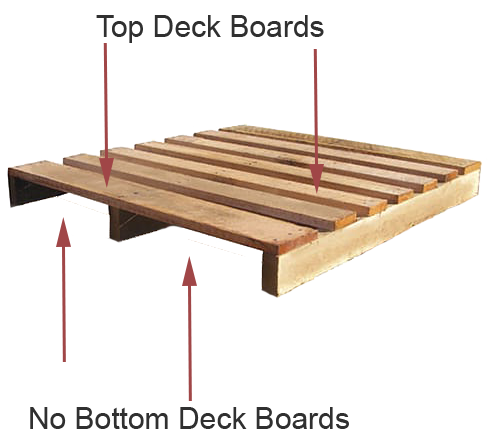

By contrast, skids only have top deck boards. Skids rest on the ground or floor on their stringers, kind of like a sled sitting on it’s runners. Coincidentally, some people call the stringers on a skid runners, and some people use the term sled or sledge to move freight or massive objects.

No one knows for sure when the skid was invented, but there’s archeological evidence that skids go back as far as Mesopotamia and Ancient Egypt. Skids were used extensively before double-faced pallets were created in the 1930’s. During World War II, there was so much cargo, supplies, and machinery to move that both pallets and skids became widely used. Skids had the advantage in the field during WWII, because skids could be more easily pulled through the sand and dirt.

Skids don’t have bottom deck boards.

Pallet or Skid: Are they used differently?

When you start discussing your requirements with a wood packaging designer, it’s important to know if you’re looking for a pallet or skid because they each function differently and are better suited for different types of applications.

As we’ve already discussed, skids don’t have bottom deck boards. That means that they often lack the stability necessary for transporting palletized items. While design, fastener choice, and wood choice obviously affects stability, those missing bottom deck boards simple make skids less stable from an engineering perspective. Skids are also more difficult for forklifts to load and unload without putting torque on the skid and potentially causing a failure.

On the other hand, skids are ideal for use as a permanent foundation for heavy machinery. The skid makes these types of items mobile and keeps them off the ground (or floor). Because heavy machinery is so… well… heavy, it’s unlikely to be moved via forklift. Using a skid, rather than a pallet, means heavy equipment can be pulled into position, if necessary.

On the other hand, skids are ideal for use as a permanent foundation for heavy machinery. The skid makes these types of items mobile and keeps them off the ground (or floor). Because heavy machinery is so… well… heavy, it’s unlikely to be moved via forklift. Using a skid, rather than a pallet, means heavy equipment can be pulled into position, if necessary.

It’s pretty hard to pull or push a pallet.

Now consider pallets:

- Pallets are super stable

- Stand up to all different kinds of palletized products

- Good design can accommodate variety of weights and sizes

- Easy for a forklift to load and unload

- Easy for a pallet jack to move

- Hold up well to to being transported and stored

- More convenient for racking

Unless you’ve got some very specific requirements that work better with a skid, you will most likely be using pallets to transport and store your products. Even if you’re not sure whether you should use a pallet or skid, your wood packaging designer should steer you in the right direction.

But does it really matter?

So, in the end, does it matter if it’s a pallet or skid? If it’s your product being stored or transported, then it definitely matters. You want to make sure you have the right type of wood packaging for your application.

It also matters when you’re talking to your wood packaging designer, because it’s important to understand what they are designing for you and why they are recommending one type of packaging over another. For example, if you’re looking for a platform for the industrial-sized HVAC systems you produce, the choice between a pallet or skid is important.

Without understanding the difference between a pallet and a skid, you may end up with something that’s poorly suited to your application.

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)