From stopping blocks to paneling, wood dunnage often goes unnoticed and underappreciated. It’s a vital resource in transportation and a lot of manufacturing industries, but a lot of people don’t really know what it is.

To understand the true impact of wood dunnage we must understand what dunnage is, its variety and uses, and why it is important to include it within your product packaging.

What is Dunnage?

Dunnage refers to any packaging component that is used to ensure the safety of products during transport. If you have ever opened a package to see a million packing peanuts, then you have seen one form of dunnage in action.

Wood dunnage is one of the most widely used and readily available pieces of transportation equipment on the market. Used to secure cargo, freight, and packages, wood dunnage plays a huge role in ensuring the stability and overall state of the products being transported. This crucial transportation tool can be found in the beds of trucks, 18-wheelers, and cargo holds across the globe.

The fact that wood dunnage is affordable, recyclable, and can be ethically sourced, is what makes it popular for many business models. It has better insulation properties than other forms of dunnage and allows for air circulation while in transit.

Used to secure cargo, freight, and packages, wood dunnage plays a huge role in ensuring the stability and overall state of the products being transported. Share on XVariety and Usage

For many aspects of the transportation industry, equipment must be precisely measured, equally weighted, and heavily regulated… that’s not necessarily the case with wood dunnage.

Wood dunnage comes in a variety of species, configurations, and sizes. Besides international shipments (ISPM-15), there are no regulatory procedures in domestic transportation ensuring specifications of wood dunnage – wood dunnage is simply a working man’s friend.

You can use wood dunnage to create space in between shipments to prevent cargo from touching or to take up space so that smaller cargo won’t shift in transit. It can be customized to each product you are packaging. There is no cut-and-dry definition of what a good configuration for dunnage is, the goal is simply to mitigate risks.

The Four Reasons Why Wood Dunnage is Important

Wood dunnage can lower the chances of product loss, strained business relationships, and headaches by preventing in-transit damage.

In-transit damage is a risk that every business must take if they are transporting their products. There are risks around every corner in this process, but wood dunnage can help to mitigate a lot of them by offering these four protections.

Physical Protection

One of the main reasons manufacturers use wood dunnage is to occupy the empty space to provide physical protection. This can be within the actual packaging. For example, using wood to prevent the product from moving within a crate or on a pallet.

It can also be used to occupy the empty space when loading the products onto trucks. Banding groove is a good example of this. It can be used to help eliminate damage caused by strapping tension and keeps other wood dunnage in place.

Physical damage can cost a lot of money, so it is worth it to make sure your products will not be thrown around during any point of their transit. That is why dunnage is important inside and outside of the product packaging.

Shock Absorption

Similar to physical protection, the wood dunnage will help to absorb shock and vibration that can happen during transit. No matter how you are transporting your products, there is no way to guarantee that there will not be any bumps or abrupt movement.

There is also the possibility of falls and impacts that can happen when loading or unloading products. The dunnage will absorb some of the impacts and help to prevent as much damage as possible to your products.

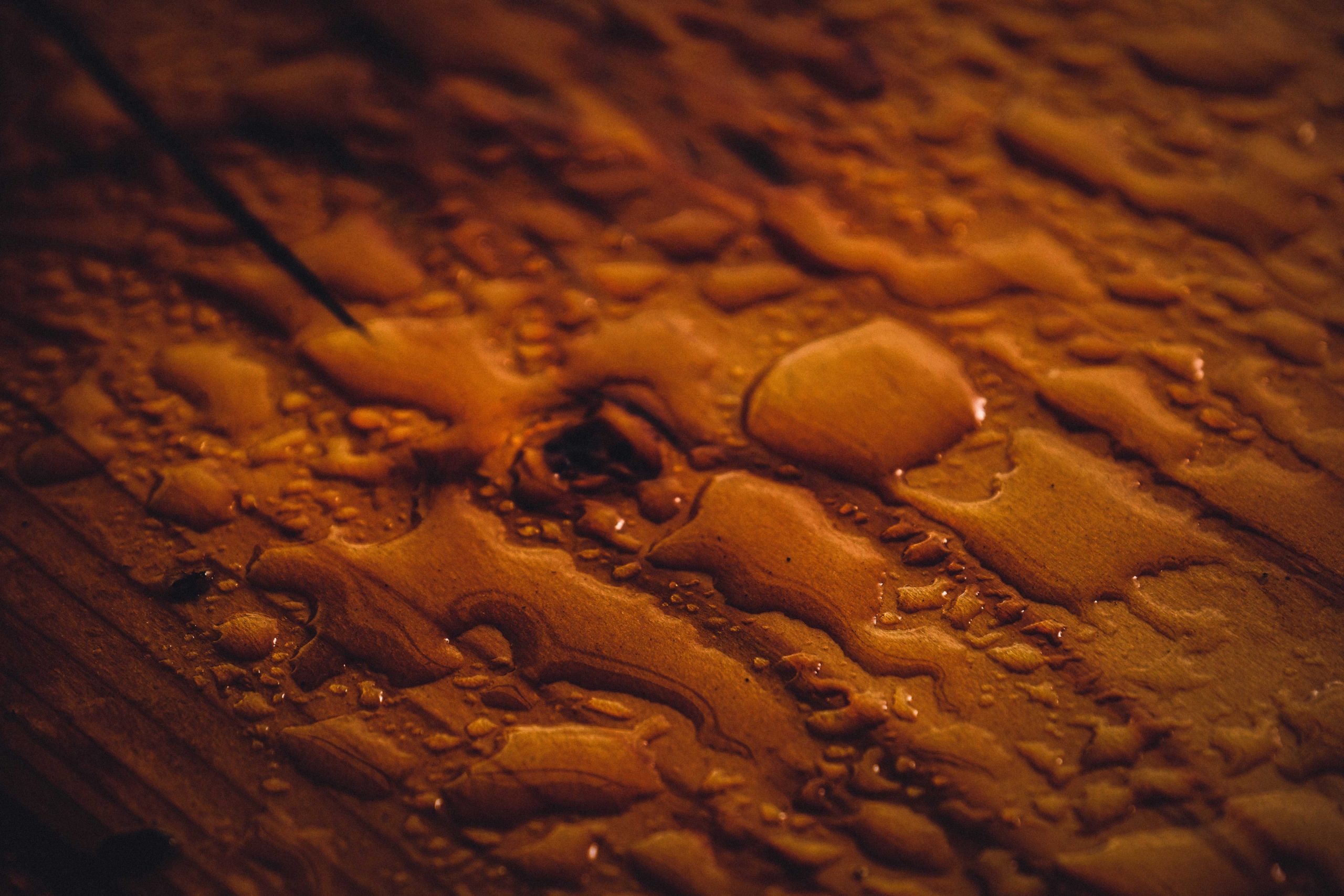

Moisture Protection

Environmental conditions are constantly changing and almost impossible to predict. Water and moisture can substantially impact the integrity of the products and the packaging they are in. Containers are designed to be resistant to water, so there is no way for drainage to occur from condensation inside the container. That is why the inside of the container must stay dry by using wood and other forms of dunnage around the packaging.

Wood dunnage can be used below pallets and crates to keep the packaging from touching the ground. This is important when the packaging could encounter water on the ground during its journey. Once again, packaging cannot be flooded, overly exposed, or sit in water without the chance of possibly damaging products.

Weight Distribution

Every package will not be the same size or weight or have it evenly distributed to make it easy to move around. Wood dunnage is used to even out the weight of packages and make them accessible to be lifted or moved safely with a forklift.

Making the packaging secure helps protect against the risk of damage to the product and injury to the employees loading and unloading. Therefore, increasing safety for all involved.

HOW CONNER HELPS

Conner Industries has been a leading provider of industrial wood and packaging solutions for over 40 years. With subject matter experts and our experienced design team, we can meet all your transportation packaging needs. Wood dunnage is just one small part of the bigger picture. Let us bring it all into focus for you!

![[PRESS RELEASE] Conner Industries Announces Major Guardian Packaging Expansion](https://conner.b-cdn.net/wp-content/uploads/2024/10/Guardian-Packaging-Expansion-500x383.jpg)

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)