The wood packaging industry is a vital part of global logistics and shipping, facilitating the transportation of goods worldwide. While wood has traditionally been the primary material used in this industry, there’s a silent hero that plays a crucial supporting role – corrugated cardboard. In this article, we will explore the pivotal importance of corrugated cardboard in the wood packaging industry. From sustainability to versatility and cost-effectiveness, corrugated cardboard has become a crucial component of modern integrated packaging solutions.

What is Corrugated Cardboard?

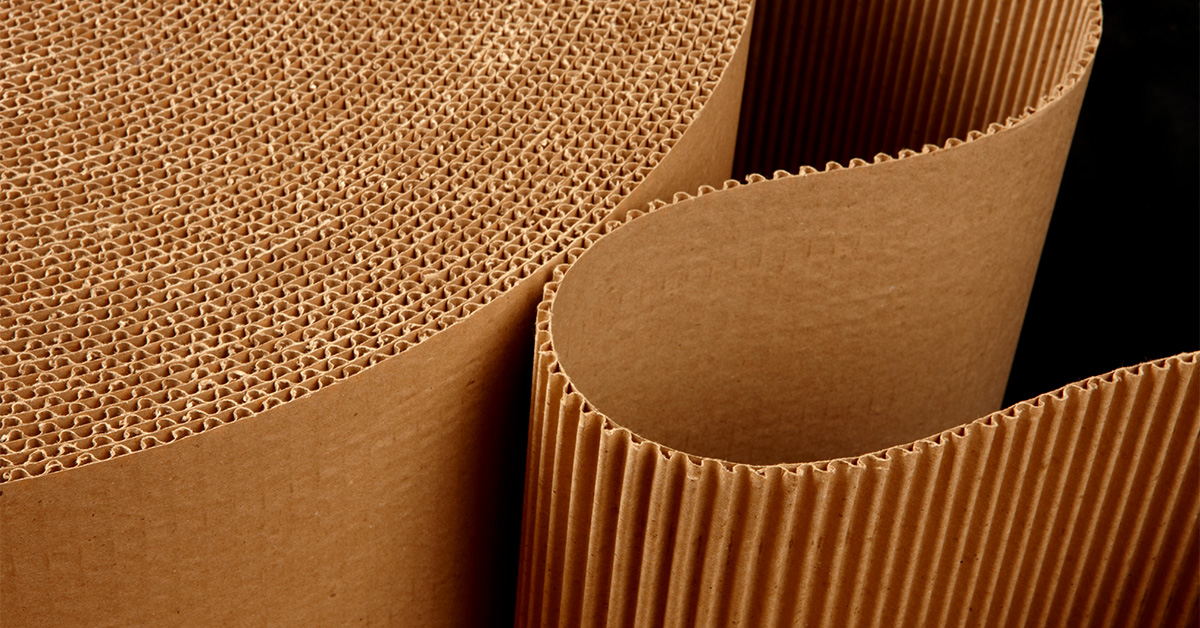

Before diving into the significance of corrugated cardboard in the wood packaging industry, let’s first understand what corrugated cardboard is and why it is beneficial.

Corrugated cardboard is a composite material made of three layers: an inside liner, an outside liner, and a fluted or corrugated inner layer sandwiched in between. This design imparts remarkable strength and durability to the material while maintaining a lightweight and flexible nature.

The Beneficial Role of Corrugated Cardboard

Versatility in Packaging Design

Corrugated cardboard’s versatility is a standout feature. It can be easily customized to create packaging solutions tailored to the specific needs of wood products. Whether it’s crating, cushioning, or protecting, corrugated cardboard can be cut, folded, and molded into various shapes and sizes.

Cost-Effectiveness

In the wood packaging industry, cost-effectiveness is one of the most important aspects of doing business. Corrugated cardboard presents a cost-efficient alternative to more expensive integrated packaging materials. Its affordability is a significant factor in reducing overall packaging expenses.

Lightweight Nature

Unlike wooden packaging, corrugated cardboard is exceptionally lightweight. This characteristic reduces the overall weight of shipments, saving on transportation costs and making it easier for workers to handle.

Sustainable Choices

Sustainability is a growing concern for many manufacturers and business owners. Corrugated cardboard is an environmentally responsible It is typically made from recycled paper and is itself highly recyclable. This reduces the carbon footprint associated with wood packaging while aligning with eco-conscious values.

Corrugated Cardboard in Wood Packaging Protection

No matter what product needs to be shipped, wood packaging is often a go to for safe transportation. Corrugated cardboard adds additional protection to your shipments. Here is how it helps:

-

Shock Absorption and Cushioning:

Corrugated cardboard’s inner fluted layer acts as a shock-absorbing cushion. It effectively dampens impacts and vibrations during transport, safeguarding wood products from potential damage.

-

Customized Fit:

The flexibility of corrugated cardboard allows for precise fitting around wood products. This customization minimizes movement within the packaging, preventing damage due to friction or shifting during transit.

-

Moisture Resistance:

While wood is vulnerable to moisture damage, corrugated cardboard can be treated or coated to resist moisture. This feature is particularly valuable when transporting wood products in damp or humid conditions.

Innovations in Corrugated Cardboard for Wood Packaging

The role of corrugated cardboard in the wood packaging industry continues to evolve with advancements in industries and innovative practices:

-

Advanced Coatings:

New types of coatings are being developed to enhance corrugated cardboard’s resistance to moisture, UV radiation, and other environmental factors.

-

Custom Printing:

Corrugated cardboard can be custom printed with branding, handling instructions, and safety information, adding an extra layer of functionality to wood packaging.

-

Sustainability Innovations:

Manufacturers are investing in sustainable practices, such as sourcing recycled fibers and reducing water usage in the production of corrugated cardboard.

The Future of Corrugated Cardboard in Wood Packaging

As the wood packaging industry faces increasing pressure to be sustainable, efficient, and cost-effective, corrugated cardboard is positioned to play an even more significant role in its future:

-

Innovative Designs:

Expect to see more creative designs that maximize the protective capabilities of corrugated cardboard while minimizing waste.

-

Smart Packaging Integration:

Corrugated cardboard packaging material can be used to elevate the packaging that you already use. It can be used as an alternative to more expensive integrated packaging materials. Corrugated cardboard is a smarter choice for many manufacturers.

-

Circular Economy Integration:

Manufacturers are exploring ways to integrate corrugated cardboard into circular economy models, promoting reuse, recycling, and repurposing of materials.

To Wrap It Up

Corrugated cardboard has evolved from being a humble packaging material to a pivotal force in the wood packaging industry. Its versatility, cost-effectiveness, lightweight nature, and eco-friendly credentials make it an important component in modern wood packaging solutions. As the industry continues to adapt to changing demands and sustainability concerns, corrugated cardboard’s role will only become more prominent, reaffirming its status as a smart packaging solution.

![[PRESS RELEASE] Conner Industries Announces Website Dedicated to Integrated Packaging Division](https://conner.b-cdn.net/wp-content/uploads/2024/05/Conner-Packaging-Blog-500x383.jpg)