Industrial packaging is important in many industries. Getting products to consumers safely and efficiently is a top priority for most businesses. But there may be some hidden mistakes that are costing you time and money.

Wooden crates, pallets, and other packaging materials are used to store, transport, and protect products from damage during transit. However, there are some common industrial packaging mistakes that companies often make, which can lead to loss of revenue, damage to products, and even safety hazards. Here are the industrial packaging mistakes you may be making:

Choosing the Wrong Supplier

There are tons of options when it comes to choosing an industrial packaging supplier. This can make it difficult to choose the one that best fits your needs. Working with an industrial packaging supplier that is not a great fit can lead to increased in-transit damage, poor quality products, and product losses. It may even affect your supply chain if industrial packaging is not delivered to you on time.

Suppliers can influence many parts of your business, which is why it is important to do the research upfront to work with one that makes your life easier. Make sure you have a clear understanding of which products and services you need. If you are unsure of what industrial packaging may work best, find a supplier with an engineer and design team to help you.

Inconsistent Quality Control

Quality control is a crucial component of industrial packaging, especially in the wood packaging industry. Companies must ensure that their wooden crates and pallets meet specific standards to protect products during shipment. Common problems in quality control include defective materials, improper sizing, and inadequate weight limits which can cause damage to shipments and even result in legal issues.

This also points back to working with a dependable supplier that prioritizes quality control on their side, so that your industrial packaging can be relied upon. Additionally, make sure that you have quality control on your side of the industrial packaging. Employees should be trained to load and unload the industrial packaging safely, so that these issues are prevented.

Common problems in quality control include defective materials, improper sizing, and inadequate weight limits which can cause damage to shipments and even result in legal issues. Click To TweetImproper Storage Conditions

Improper storage conditions, such as moisture, can cause damage and weaken the quality of wooden industrial packaging. This can lead to increased replacement costs and issues with legal compliance. To maintain packaging quality, wooden pallets and crates must be stored in dry and well-ventilated spaces to prevent power losses during storage, transportation, and usage.

Failure to properly store your industrial packaging can lead to a loss in integrity, which can lead to unexpected costs for you. In-transit damage and product loss can lead to many unexpected costs and less customer satisfaction. It is best to use new pallets and store them correctly, so that transportation is always a breeze.

Ignoring Regulations and Standards

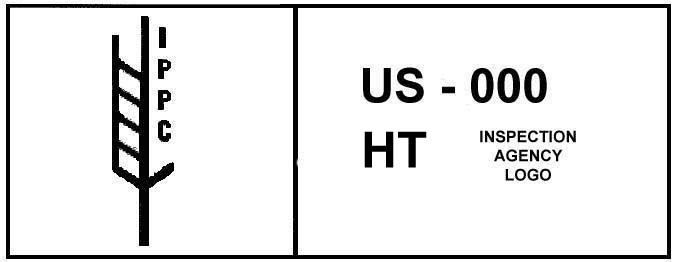

Regulations and standards are essential in the packaging industry and ignoring them can lead to safety and legal compliance issues. Companies should adhere to relevant standards like ISPM-15, which requires wood packaging materials to be fumigated or kiln-dried to prevent the spread of invasive pests.

Working with a supplier that has knowledge of the regulations that your industry must follow is imperative. Your supplier will be able to make sure that all your industrial packaging needs are being met in the most cost-effective way. You don’t want your products stuck at a border because regulations were not followed correctly.

Attributing Cost Savings to Lower-Quality Materials

Cutting costs by using lower quality materials can lead to final products lacking the necessary protection to ensure safe delivery. Instead, it is recommended to look for ways to reduce costs through innovation and efficiency improvements rather than relying on lower quality materials.

This applies to those that choose to work with recycled pallets instead of new pallets. It may save you money up front, but recycled pallets cannot be trusted the same way new pallets can be. There may be damage that is not seen on the outside and leads to issues later. New pallets may cost more money to begin, but they are the most reliable wooden industrial packaging choice.

To Wrap It Up

Avoiding these common industrial packaging mistakes can help companies to safeguard their products, save money, and remain compliant with the relevant regulations. Companies should strive to work with the best suppliers, improve their quality control, provide appropriate storage conditions, observe relevant regulations and standards, and look for innovation rather than compromise to cut costs. Ultimately, investing in high-quality industrial packaging can result in higher customer satisfaction and lower liability risks, as well as increased profits in the long run.

Conner Spotlight

Conner Industries is a leading producer of industrial packaging solutions. We specialize in pallets, crates, skid parts, integrated industrial packaging solutions, and other services customized to what each customer needs. We know how important supplier relationships are and we take them seriously.

We have thousands of different wood products, including wholesale lumber, panels, dunnage, banding groove, and pallet lumber. We have contracts with North America’s largest softwood producers, so that we can provide the best deal possible for our customers. With our 14 locations nationwide, we can help customers meet their industrial packaging needs and keep supply chains moving.